In January 1959, Britain’s railway modernisation programme was gathering momentum. Among the most significant developments of the period was the introduction of a new generation of Type 2 mixed-traffic diesel-electric locomotives, designed to handle both passenger and freight duties across the network.

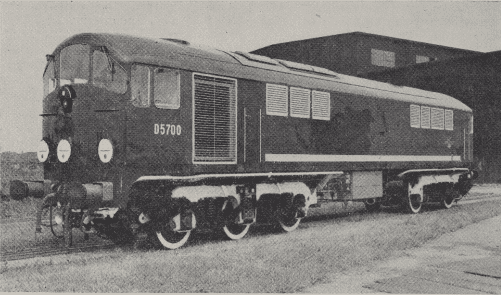

The Railway Magazine reported on the delivery of twenty 1,200hp diesel-electric locomotives, numbered D5700–D5719, which were being supplied by Metropolitan-Vickers Electrical Co. Ltd. to the British Railways London Midland Region. All were allocated to Derby, where they were intended for use on both passenger services and freight workings within the Midland Division.

Dimensions and layout

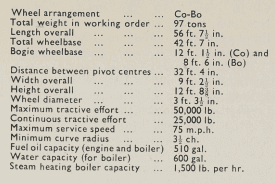

The locomotives featured a Co-Bo wheel arrangement, weighed 97 tons, and measured 56ft 7in over buffers. Each cab offered a full-width body and centralised driving position, allowing operation from either end. The body structure was divided into four main compartments: two driving cabs, an engine and radiator compartment, and a generator and boiler compartment.

From the history of steam through to 21st century rail transport news, we have titles that cater for all rail enthusiasts. Covering diesels, modelling, steam and modern railways, check out our range of magazines and fantastic subscription offers.

A key design feature was accessibility. Air intake positions were carefully arranged to reduce contamination, while removable roof sections and multiple access panels allowed straightforward maintenance of auxiliary machinery, cylinder heads, fuel pumps and boiler components.

Power and performance

At the heart of the design was a two-stroke diesel engine, continuously rated at 1,200hp at 625rpm, with a one-hour rating of 1,320hp. Safety systems ensured automatic shutdown in the event of overspeed, low lubricating oil pressure or excessive coolant temperature. Twin exhaust outlets were positioned to avoid interference with overhead wiring.

Each of the five axles was fitted with a nose-suspended traction motor, permanently connected in parallel. Drive was transmitted via a single-reduction gear with a ratio of 15:67, providing resilience between hub and rim through the gearwheel design.

Electrical systems and controls

The locomotives featured automatic control of generator output and motor field strength, ensuring consistent power delivery regardless of speed or load. This was achieved via a servo-mechanism responding to hydraulic signals from the diesel engine governor.

Driver instrumentation included a master controller, brake valves, speedometer, tachometer, brake gauges and warning indicators for engine stopped, wheelslip and alarm conditions. Illumination intensity could be adjusted for all lighting conditions, from bright sunshine to total darkness.

Comfort and auxiliary equipment

Cab heating was provided by tubular electric heaters, supplemented by a foot warmer at the driver’s position. Fresh air ventilation used filtered air drawn from the traction motor cooling system, with heated air supplied to demister ducts for the cab windows.

Auxiliary equipment included air compressors supplying 100lb per square inch for braking systems, electro-pneumatic controls, sanding gear, whistles and windscreen wipers. Additional motors powered radiator fans, ventilation systems and ancillary equipment, while a battery was provided for engine starting.

Designed for the future

Provision was made for future developments, including replacement of side buffers with central automatic couplers, reflecting forward-thinking design philosophies. Fuel and boiler water tanks were incorporated into the underframe structure to maximise strength while minimising material usage.

Together, these locomotives represented a significant step in Britain’s transition from steam to diesel traction — combining power, flexibility and maintainability at a pivotal moment in railway history.

The original article appeared in the January 1959 issue of The Railway Magazine. The entire archive of issues, dating back the the 1800s, is available to browse for subscribers of The Railway Magazine. To subscribe, please visit https://www.classicmagazines.co.uk/the-railway-magazine