This article is an archive feature reproduced from The Railway Magazine, 1965, offering a snapshot of how British Rail was reshaping freight handling more than 60 years ago.

In 1965, British Rail undertook a major reorganisation of freight and coal traffic across Somerset by concentrating operations at a newly developed two-section goods and coal depot at Taunton. The move replaced services previously provided by 30 small local stations, reflecting a nationwide shift in railway freight strategy during the mid-20th century.

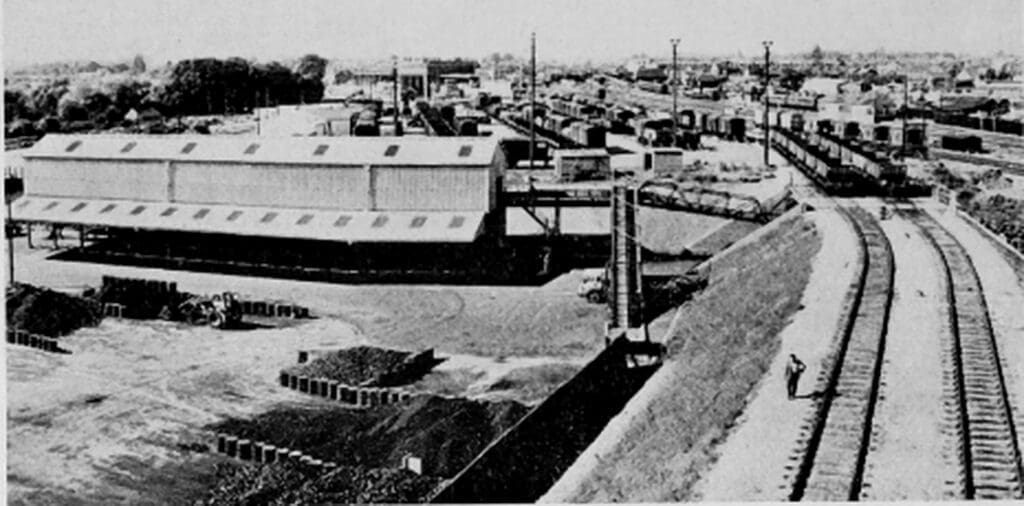

The Taunton depot, officially opened by the Mayor of Taunton, served a 30-mile radius and was located adjacent to the town’s passenger station. Its notice of opening appeared in The Railway Magazine in November 1965, documenting a significant moment in British Rail’s drive for efficiency.

From the history of steam through to 21st century rail transport news, we have titles that cater for all rail enthusiasts. Covering diesels, modelling, steam and modern railways, check out our range of magazines and fantastic subscription offers.

Before centralisation, freight and coal traffic was handled at stations including Minehead, East Anstey, Burlescombe, Ilminster, Martock, Somerton and Bridgwater. Under the new system, traffic was collected and delivered by a fleet of road vehicles, while customers with private sidings continued to be served directly by rail.

The depot was designed primarily to handle the transfer of small consignments between railway-owned delivery vehicles and standard British Rail wagons. Annual throughput was projected at 130,000 tons, with goods handled inside a large shed providing rail access on one side and road access on the other — a layout typical of the period’s modern goods depots.

Supporting the operation were 30 road vehicles, alongside on-site distribution and servicing facilities. The depot also enabled wagon-load traffic to be consolidated for single destinations, simplifying loading at Taunton and unloading at centres as far afield as Glasgow.

A key feature highlighted in the 1965 article was the mechanised coal-handling plant, designed to minimise breakage by reducing the height from which coal fell. Hopper wagons discharged coal via a bridge into conveyor systems feeding the main building, with a handling capacity of 14 tons per hour.

Coal could be loaded directly into lorries, discharged into storage hoppers for bulk delivery, or bagged and weighed using semi-automatic equipment. This system reduced dust and eliminated much of the heavy manual labour associated with traditional coal handling, while also providing ground storage space.

Coal and solid fuels were supplied from smaller collieries in the Midlands and South Wales, with trains arriving and departing to fixed schedules. Daily capacity was approximately 500 tons, equating to 75,000–80,000 tons per year.

The depot was operated by Taunton Coal Concentration Limited, a company established to avoid complications that might have arisen had British Rail acted as a wholesale coal distributor — a notable detail reflecting the regulatory and commercial environment of the time.

Subscribe to the Railway Magazine and you can access the full magazine archive, going back to the 1890s!