If you thought that replacing a shed roof on a motive power depot would be easy, think again. Should you feel more adventurous, you can always add to the complexity by installing a 6.3-ton overhead travelling crane.

What really opened my eyes to this task was an article in the Severn Valley News by Bridgnorth shedmaster Martin White, explaining the logistics involved in this huge task. The entire shed will be closed for four months from May, becoming a construction site and fenced off to all SVR workers. It has to be emptied completely, apart from fixed items like the wheeldrop and frame lift, before work can commence, and some heavy items of machinery will have to be repositioned.

Those readers who have ever had a new roof on their house have a small understanding how it is done – from the scaffolding, access for deliveries, storage of materials, getting materials onto the roof, health and safety, security… and don’t forget, somewhere for tea and toilets, preferably separate! Can you imagine completely emptying your house for the work to be carried out? Then, of course, there is the fickle British weather that can throw the proverbial spanner in the works at short notice, from high winds to torrential rain.

However, these works are essential and it was brought home one day when I was in the shed. It was raining and people were struggling unsuccessfully with a large tarpaulin, attempting to cover a tender they were working on. The new cylinder blocks of SVR flagship GWR 4-6-0 No. 4930 Hagley Hall were soaked, as well as its paintwork, causing extra unnecessary work.

A recent survey reported that “the roof is worn out, full of holes and leaks badly. It has been estimated that the roof has no more than a two-year lifespan in its current condition and could potentially put a stop to works at the locomotive shed if the problems are not addressed”.

The problem was caused by condensation running down the inside of the roof and settling around the fixings of the purlins and rusting them. Over time, the condensation has rotted away the fixings holding the roof on and the purlins themselves.

On March 25, 1967, Collett 0-6-0 No. 3205 arrived in Bridgnorth with four carriages soon after the Severn Valley Railway bought the line for £25,000. There was never a locomotive shed at Bridgnorth before then. The goods shed was initially used in the early heritage era as a locomotive maintenance shed, but this proved far too small and unworkable. The original idea in the 1970s was to have a covered area for locomotive storage during the winter, but over time it evolved into a workshop.

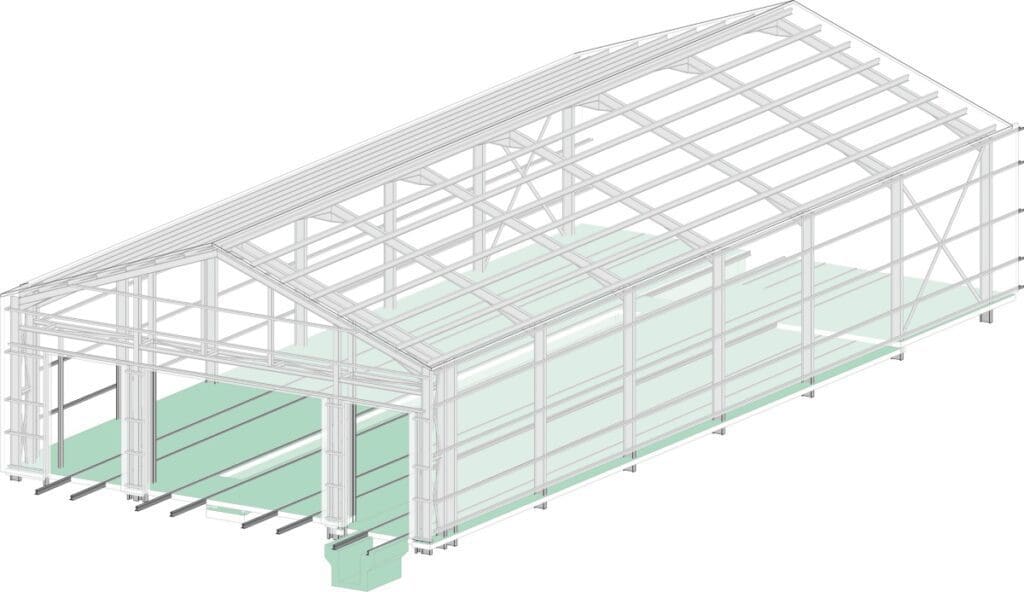

Construction of the present shed began in 1976 using parts of a large disused building from Portskewett near Severn Tunnel Junction. The pits were dug the same year and the building was completed in 1977.

In 1979 it was extended, utilising the ex-BR diesel depot building from Heaton Mersey, Stockport, purchased in 1972. This structure was added onto the ex-Portskewett shed, adjacent to the existing goods shed. Outside, the front of the shed is an original small single-storey brick building on the left.

The goods shed still exists and for many years has been used as the machine shop, and this will remain fully operational and untouched by the construction works. The boiler shop is a newer building tagged onto the end of the shed, so works will continue as near normal, but it could be used for running repairs if essential.

Inside the shed is a frame lift built by Ransomes & Rapier Limited in 1937, capable of lifting a maximum of 15 tons per jack. It originally belonged to the London Passenger Transport Board at Lillie Bridge, Kensington, and was installed shortly after the ex-Portskewett shed was completed. Inside the ex-Heaton Mersey building, a section was partitioned off during the 1980s for a paintshop. Improvements were made to the main shed in 2009 with the installation of roller-shutter doors and side windows, but little has been done since.

What has become a really useful tool is the wheeldrop that was installed in 2010. It came from 15C, Leicester Midland motive power depot, and is capable of dropping wheels up to 7ft diameter – big enough for that of a Jubilee or Duchess. Castles, A4s and A3s are 1in smaller and Kings are only 6ft 6in, so it is capable of dropping all preserved main line locomotives’ wheels. Neither of these items can be removed for the roof works.

Now is the time to bring this important building up to modern standards, especially with the excellent work done in keeping our heritage steam locomotives running. If the works do not take place soon, the roof would have to be inspected every three months to ensure it is safe; should it become unsafe, the shed could be forced to close without warning and therefore cause significant difficulties for the railway. We have seen this problem elsewhere – and the costly repercussions. As a result, some important decisions were made and a plan of action developed to tackle the issue with minimum delay.

Fortunately the SVR has a strong volunteer base which realised the problem and sprang into action, giving many hours of free time. These works will be volunteer-led throughout, saving the railway thousands of pounds.

In November there were five locomotives inside the shed being worked on. Going through the final stages of rebuild is Hagley Hall, which will be the first to return to steam next year, followed by Stanier 2-6-0 No. 13268. There is now a race against time to get these locomotives completed before the shed closes in May.

GWR 2-6-2T No. 4150 should be off its jacks by then and become a rolling chassis, making life easier, and new-build BR Standard 3MT 2-6-2T No. 82045 will have to be removed from the shed. Beamish Museum’s Sharp Stewart 0-4-4T No. 4085 of 1895 Dunrobin is in the yard and work is continuing on its restoration; its boiler is inside the boiler shop.

Meanwhile, regular works continue with GWR 2-8-0 No. 2857 inside for a regular valve and piston examination, and GWR/Port Talbot Railway 0-6-0ST No. 813 has recently received replacement boiler tubes.

Needless to say funding is fundamental for any works to take place. Questions have to be asked – how important are the works, is it really essential, and what happens if you cannot afford it? In this case, delaying replacement was not an option because it would cost considerably more in the future, especially with the escalating cost of steel and building materials. The Home and Dry appeal was to be initially launched in March 2020 but was postponed as Covid-19 ground the country to a halt.

In April this year, the appeal went into full gear with the launch of a 90-second film by Lesley Carr on social media and through the mail to the SVR supporter base of members, donors and shareholders. Funding was split into three phases. The first covers the roof and wall cladding, electrical installation and construction of the crane foundations, at £385,000. The second is for the infilling of road two and moving larger items out of the shed, at £25,000. The third is for steelwork for the crane and the crane itself, at £65,000. So far there are sufficient funds to enable phases one and two to start. The appeal got off to a flying start, raising £265,000 in the first 12 weeks, and then slowed to a steady £30,000 per month during the summer and early autumn. A raffle raised £31,000, the second highest in SVR history; a total of 5000 people have donated or purchased raffle tickets so far. There are two grants to the value of £55,000 also in the pipeline.

The total raised so far is £430,000, so a push is now on for the final appeal of £45,000 for the crane. The total needed is £475,000.

What has not helped is the continued escalating material costs. The new steel purlins have doubled in price and the roof sheets by 25%, all due to general shortages caused by Covid-19. Fundraising manager Sue Chance said: “We have been overwhelmed by the generosity of our supporters at the SVR – they clearly understand the necessity of this project to improve the Bridgnorth Locomotive Works, where our locos are restored and maintained, to keep the railway operational. We have raised enough to undertake phases one and two of the project and are now making a plea to raise the final £45,000 needed to ensure the full works can be undertaken.”

Being in a conservation area makes matters difficult. The footprint of the building will not be changing, but simpler aspects – like the change of colour on the roof and cladding – had to be approved. Plans were submitted to Shropshire Council by architect and SVR volunteer Ben Wright in June. Roof lights and ventilation cowls were included to avoid changes later, and all were approved in early September. The conservation officer decided on the colour of the external finishing and anthracite was chosen.

Volunteer project leader Antony Bartlam, who is also a volunteer fireman, has so far spent almost 300 hours on the project, from CAD drawings to the essential structural calculations, after starting work on it in 2018. Antony will be overseeing the project dealing with all aspects of the works.

One interesting aspect of the design was the omission of roof lights over roads four and five due to the possibility of them melting, should a warm locomotive be positioned underneath. Nick Yarwood, who dealt with the Falling Sands Viaduct restoration project as a volunteer, is involved with the contracts and time planning; there are more than 130 items on the time programme alone. Local companies will be used as much as possible and many have volunteered services for free, such as the completion of a ground investigation report, which included drilling boreholes for the foundations. Contractors have been appointed and estimates accepted regarding the roof and the electrical installation. Orders have been placed on materials that have long lead times, like the cladding, which is currently six months.

Antony said: “With the current economic climate and material logistics, this project is proving challenging.

“There is a massive amount of work to do before the work starts to clear the shed, which has to be carried out on time as the roof sheets are already on order and have a delivery date which cannot be altered. There is a superb team behind these works and I know that with the assistance of the many volunteers we have, this will be a success.”

Before any works can commence, the shed has to be cleared of all tools, cabinets, spares and everything that was thought might be useful one day! A general clear-out will take place and containers will be used for general storage; some will require access but others will be closed off for the duration. Of paramount importance is the amount of useable rail space at Bridgnorth and every square inch will be utilised, with unused stock moved to other locations on the railway. At the northern end, referred to as the boiler shop yard, there are several sidings leading towards Bridgnorth Tunnel. These will be full but access to the boiler shop will be kept relatively clear should anything untoward happen and a locomotive needs attention.

All locomotives operating from Bridgnorth will be turned to face south so chimneys are furthest away from the shed, reducing fumes for those working on the roof. As an added safety measure, arrangements will be put in place for the contractors to cease work when shunting takes place in the vicinity of the scaffolding.

Due to the reduced size of the yard and all locomotives facing south, Bulleid West Country 4-6-2 No. 34027 Taw Valley will not fit over the temporarily shortened motive power depot yard pit, which is essential for oiling up, so for the time being will operate out of Bewdley instead of Bridgnorth.

Martin White said: “Everything that is currently in the main shed at Bridgnorth motive power depot needs to be removed, or at least relocated, to give the contractors unhindered access. The fixed equipment, such as the locomotive lifting jacks, along with the largest machine tools, will be left inside but will be cocooned to protect them during the works. All of the smaller items, tool lockers, stores, small machines and items of plant, etc. will be given alternative storage. The welding and fabrication area will be temporarily relocated as it is a must-have facility that will be required during the disruption. The planning for all of this is already well advanced and some tasks and actions have commenced, but many will be starting in earnest before the end of 2021.

“We’ve done similar things before, such as when the wheeldrop was installed and the end doors were added to the shed. But this is the first time that we will have handed the building over in its entirety to contractors for such a long period. Hence, there will be significant disruption to the workforce, paid and volunteer, but we will all work around any issues to ensure that we literally ‘keep the wheels turning’.

“With regards to the SVR locomotives, those undergoing restoration and build, such as Nos. 4150 and 82045, will be provided with a berth in the MPD yard so that work can continue, although in different circumstances to those which the loco owning groups have become accustomed. Everyone knows that the investment in time and effort, in addition to the money, is very worthwhile and will result in something that brings massive benefits to all the people who work within the shed and to the SVR steam loco fleet.”

Before construction can commence, a considerable amount of the installed services – such as electric cables, IT and telephony infrastructure – will have to be removed from the wall cladding to which it has been fixed over the last 20 years. Some of this is three-phase equipment in metal conduit and trunking, and which all has to be made safe beforehand.

It is not just a simple case of replacing the roof – all the purlins need replacing, too. The purlins run between the main steel frame and support the roof sheets. The lighting inside the shed has always been poor with little natural light filtering through, but this will all change because at least 15% of the roof panels will be translucent to maximise daylight, and all the roof cladding will be fully insulated. New energy-efficient sustainable lighting utilising LEDs will be installed throughout, giving full illumination in every part of the building, thus creating a much better working environment. The external walls will be clad and insulated to keep the heat in during winter and reduce noise for the neighbours. While all the roof works take place and the shed is empty, it makes perfect sense to put in the footings for the travelling crane; work that would be difficult to do afterwards. On the west side there is bedrock one metre down but on the east side it is four metres down, so piling will be needed.

Various other essential works will take place internally. The sunken floor around the frame lift will be levelled, along with the floor of road two (on the east side inside the shed), which, for historical reasons, is lower than the main shed floor. This will give a level floor throughout reducing trip hazards. Afterwards, the rails in road two will disappear and the space used for work benches and machinery becoming a running machine shop, much needed at present. A set of buffer stops will be fitted inside as a safety measure should something untoward happen outside.

Talk regarding a crane started more than four years ago, when it became apparent how much time and money this would save. A second-hand crane has been identified that is hopefully suitable for the job.

The crane is restricted in headroom by the height and pitch of the roof, so detailed consideration is being given to obtain a hook height that is as high as possible to make the most use of it. Having a lifting capacity of 6.3 tons, it will be capable of lifting cylinder blocks (the blocks for No. 4930 weigh 2.7 tonnes each) and locomotive wheelsets, including large crank axles, drivers and tender tanks. Capacity for lifting boilers is available in the boiler shop next door.

Construction will commence in May and is projected to take about four months. All this is designed to fit in between the SVR’s two major steam events: the April 21-24 spring gala and the autumn one traditionally held around the end of September. Access for the construction works will be from the north end through the present paint shop, which will be completely cleared and a temporary partition built separating the site from access to the machine shop inside the old goods shed. There will be no scaffolding on the western side of the shed, as this area will be used for the site huts and general storage. Coal deliveries will continue down this side, as before. At the south end, most visible to the general public – especially from the footbridge at the station – there will be scaffolding erected and a protective security screen separating the construction site from the MPD yard.

After about 12 weeks, once the main structure of purlins and the metal liner sheet is fitted, the roof will be safe to walk on and watertight. The shed can then be handed back for internal fitting out, including the crane and electrical installation. Meanwhile, the insulation and final roof sheets can be fitted. The maintenance yard is needed at all times for coaling, preparing and watering locomotives. A temporary cover will be fitted over road four and a workshop container on road three to make conditions a little more convenient for maintenance staff. This area will be off limits to construction workers, as will the construction site itself to SVR workers and volunteers. Road one, between the shed and platform two, must be completely cleared of all rail vehicles for scaffolding. After cladding installation the wall will increase 20cm on the exterior, thus rendering the siding virtually unusable due to insufficient clearance. Investigative work is ongoing to determine its future for rail vehicles.

Health and safety is crucial for the safety of all workers on site and it is clear that a considerable amount of time and thought has gone into this by the segregation of the two areas; this should also speed up the work considerably. Security is important, so when the roof panels are replaced it will be done section by section. The burglar alarm panel and wiring will be repositioned so it is accessible inside areas undisturbed by the works. Random security patrols will continue as before. As with all contracts, there is a contingency fund but it is hoped this will not be needed. If all goes well, as was the case with the Falling Sands Viaduct project, which was delivered on time and on budget, the SVR will understandably be very happy. There will be no half-term running in February. Weekend services resume on April 2-3, and daily running for the Easter period starts on April 9 coinciding with the school holiday.

Upon completion it will not be a simple task of moving straight back in. The new location of equipment, tooling and machinery is being planned even at this stage, but a lot depends on how the locomotives have performed throughout the closed period and what works are needed. As the emptying of the shed commences in preparation for the works, Heritage Railway will keep you updated of developments on how the motive power depot continues to operate through this difficult time. You can also keep updated on other news from the SVR by visiting the railway’s website here. A special thank-you to Martin White and Antony Bartlam for their help in the production of this feature.

➜ To help the works progress as quickly as possible, all donations are welcome. This can easily be done here . For further information, see the SVR Charitable Trust’s webpage. Donations in excess of £75 not only pay for a steel purlin for the roof, but also secure a limited edition Alan Reade print of Bridgnorth Locomotive Works.